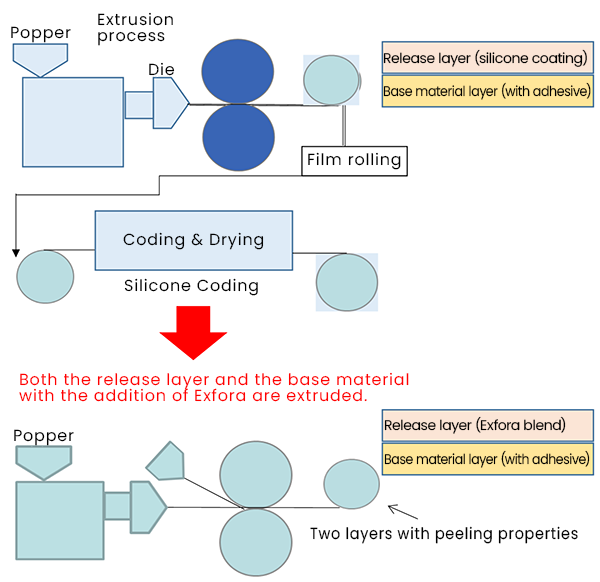

Exfola™ is a true tri-block polymer consisting of polyethylene and silicone.

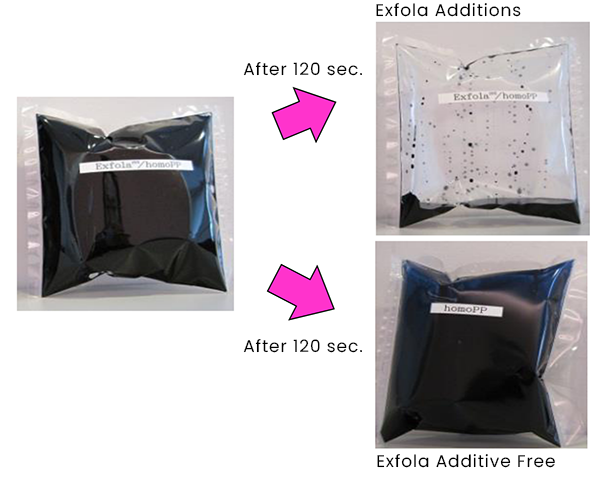

By adding a small amount of polyolefin material during molding, it is possible to give the characteristics of silicone (releasability, water and oil repellency, and abrasion resistance) to the surface of a molded product.